3D Printing of Steel

Our Projects

Our active projects have seen us work with Cranfield University and Imperial College London to further develop the technology and WAAM processes. In addition to these projects, we have worked closely with architectural firms to design and print innovative solutions to replace standard steel connections. More recently, we have printed a structure that resembles a double helix. The structure, designed by one of our architectural partners, will be used to form part of an ornate canopy ceiling. The 3d printing process allows designers and artists to break the norm and create what has never been made before. Collaboration between the steel industry, architects and education is essential for the continued development of this cutting-edge technology.

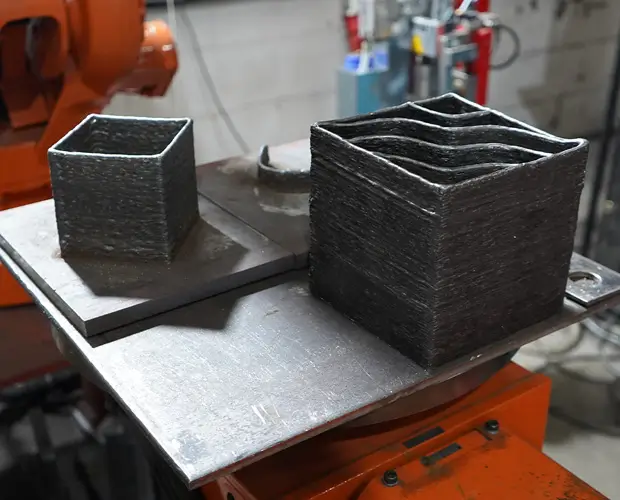

Box Structures

Our earliest prints were 2d designs printed layer upon layer, here you can see some of these designs. At the start of our process, printing objects such as these was a huge step forward. Synchronising the welding gun speed, temperature and feed with the moving robotic path took the team several days of prep work before the system could even be turned on. However, once we got the system up and running, it was able to produce some amazing results. The level of detail and accuracy that we were able to achieve with these prints was incredible, and it really opened up a whole new world of possibilities for us. We are now able to produce prints with less preparation time and with more complex paths. We are constantly exploring new ways to push the boundaries of what is possible.

Tiger Print

Going from printing straight lines to curves was a big step forward in better understanding the capabilities of our system. The implementation of new software allowed our robot to start moving more freely when making prints. Similar to the box structures, this was printed from a 2d design layer upon layer. The main difference with the tiger design is the free flowing curves and angles in the design. This results in a more organic and natural look for the final product. In terms of construction, it is also slightly more difficult as the pieces need to fit perfectly together in order to create a fluid design. Despite the challenges, we are very happy with the end result and believe that it was worth the effort.